Fördertechnik und

Automatisierungssysteme GmbH

Deutsch

Englisch

Pack conveying systems

- Back-up roller conveyor

- Distribution units

- Flat top chain conveyor

- Flat top chain conveyor with stop and timing

- KEG transportation system

- KEG turning device

- Pack angular transfer unit

- Pack elevator

- Pack pusher

- Pack rotating device

- Pack stopper

- Roller conveyor

- Rubber belt conveyor

___________________________________

Pack conveying systems |

|

Example:

Pack conveyor in a German brewery

Pack conveyor in a German brewery

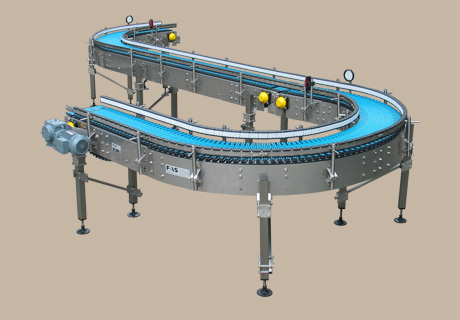

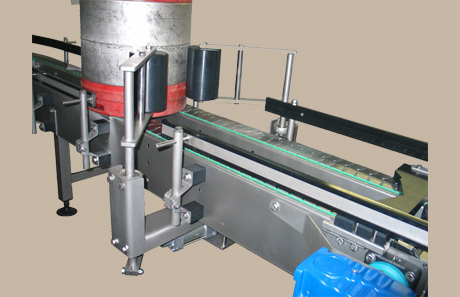

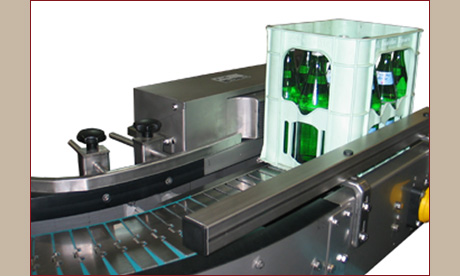

Back-up roller conveyor |

|

- Suitable for trays and plastic crates in packaging lines

- Low back-up pressure roller chain in different widths: 7 1/2, 10 or 12 inch

- Single-lane or double-lane design available

- Roller crossover for save and smooth transfer between the individual conveyors

- Special sliding blocks for low-noise chain return, free access to the return chain

- Curves in DUAL-magnetflex design

- Stainless steel design

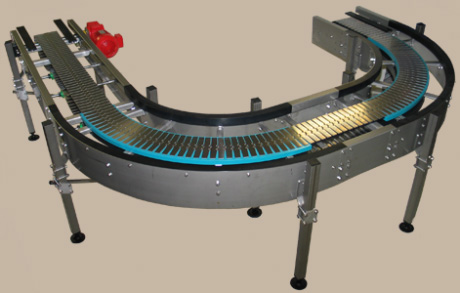

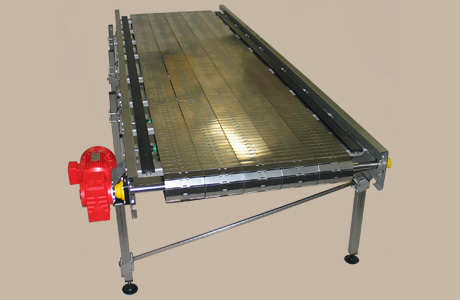

Flat top chain conveyor |

|

- Suitable for trays and plastic crates in packaging lines for returnable and non-returnable bottles, empty crates and crates with empty and full bottles

- Middle chain lane provides a safe and low noise transport

- Covers designed as lateral guides, no additional guide railings necessary

- Stainless steel design

- Curve-going model with magnetic chain, TAB chain or chain with bevelled guide shoes

- Special design (for example as distribution unit)

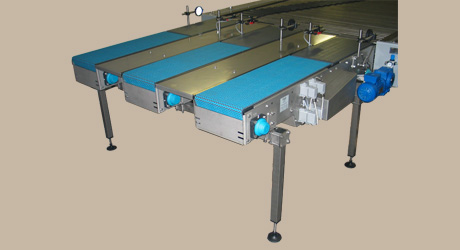

Flat top chain conveyor with stop and timing |

|

Example:

3-lane stop- and timing conveyor in front of a line distributor

3-lane stop- and timing conveyor in front of a line distributor

- Suitable for shrink packs, trays and plastic crates and cartons in packaging lines for returnable and non-returnable bottles

- Stainless steel design

- Available with flat top belt and grip top belt

- Suitable as pack stopper and pack infeed unit

- Chain support by plastic guiding profiles

- Knife-edge chain deflection for small packs

- Options: barrel-type motor as drive motor, frequency control

KEG transportation system |

|

- Suitable for trays, empty plastic crates, crates with empty and full bottles

- Frame in stainless steel design

- Belt support by rollers or sliding plate

- Options: barrel-type motor as drive motor, frequency control

KEG turning device |

|

- Available as selective turning version or forced turning version

- Optimized for integration in FAS KEG conveying systems

- Stainless steel design

Pack angular transfer unit |

|

- Lifting device motor driven

- Toothed belt conveyor with two or three belts

- Stainless steel design

- Compact design

- Low maintenance

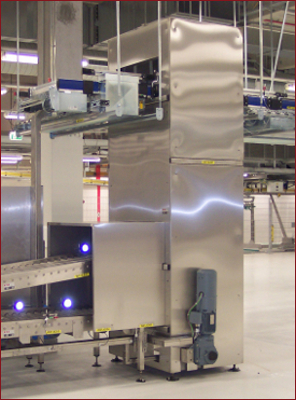

Pack elevator |

|

- For the connection of different floors or conveying levels

- Multiple stopping points are possible

- Variable design, e.g. U- or L- design for material flow

- Lifting drive unit positioned at the bottom with two toothed belts

- Stainless steel design or lacquered mild steel

- Low maintenance

- High life span

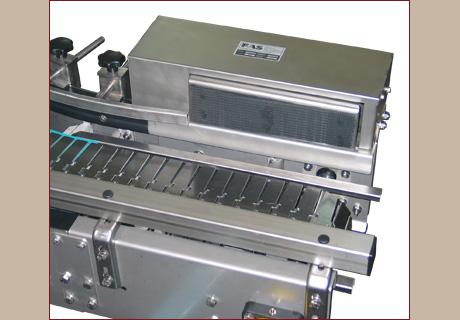

Pack pusher |

|

- Suitable for sorting plastic crates in packaging lines for returnable and non-returnable bottles

- Capacity of up to 3000 crates per hour

- Stainless steel design

Pack rotating device |

|

- For rotation of plastic crates or cardboards from longitudinal to transverse or vice versa

- rotating function by speed difference between the single flat top chains

- speeds can be set continuously by frequency converter

Pack stopper |

|

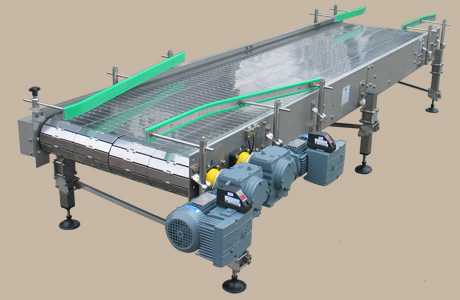

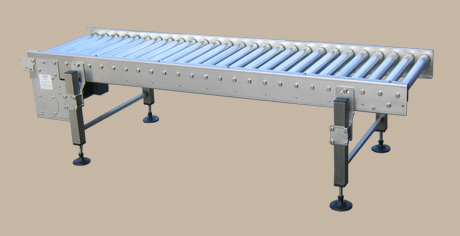

Roller conveyor |

|

- Suitable for trays, empty plastic crates, crates with empty and full bottles and KEG drums

- Frame in stainless steel design

- Rollers offered in plastic, galvanised steel and stainless steel

- Optional fixed or friction rollers

- Covers designed as lateral guides, no additional guide railings necessary

- Low maintenance, good accessibility

Example:

Gravity roller conveyor with curve and pick-up area, e.g. for KEG conveying

Gravity roller conveyor with curve and pick-up area, e.g. for KEG conveying

Example:

Curved driven roller conveyor with conical rollers

Curved driven roller conveyor with conical rollers

Rubber belt conveyor |

|

- Suitable for trays, empty plastic crates, crates with empty and full bottles

- Frame in stainless steel design

- Belt support by rollers or sliding plate

- Gradients or descents up to 18 degrees are possible

- Swan-neck conveyors are available for big gradients

- Universal adaptable supporting foot system

- Options: barrel-type motor as drive motor, frequency control

Sitemap

___________________________________

© 2008 FAS GmbH - Zum Pier 63 b - D-44536 Lünen. All rights reserved.

© 2008 FAS GmbH - Zum Pier 63 b - D-44536 Lünen. All rights reserved.